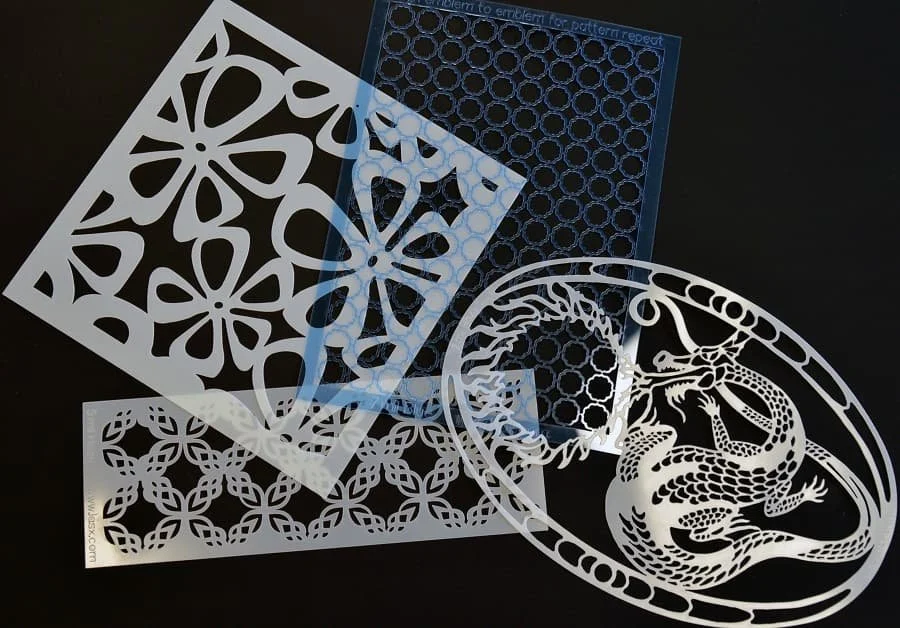

Stencils

Where precision meets possibility.

Choose laser for stencils.

Using alternative mechanical methods can negatively impact the quality of stencils. Laser processing technology eliminates jagged edges and other undesirable effects, and instead, creates stencils with smooth contoured arc segments—delivered quickly and precisely.

Design simplification

As a one-stop shop, LasX offers a comprehensive service for stencil production from design consultation to material sourcing to stencil packaging.

Remain nimble

Our laser-enabled digital workflow ensures LasX services remain competitively priced and responsive to short- and long-run production needs.

Waste reduction

Traditional stacking creates waste with the top and bottom layer being discarded, whereas laser technology cuts each stencil individually delivering the highest quality possible without material waste.

On-demand production

Our laser processing technology is digitally reconfigurable, minimizing setup time and eliminating the expensive downtime associated with production changeover.

The LasX Advantage

LasX commits to translating an idea/prototype into a manufactured stencil that fulfills artistic intention, while taking into consideration material and project scope. Our LaserSharp processing technology is well suited for achieving intricate designs not possible with traditional die cutting.

Delivery Options

Bulk Stencil Delivery

Retail-Ready Delivery

Roll-Format Delivery

How can LasX help you?

Stencil Solutions

Contract Manufacturing Services

-

Need a one-stop shop? LasX provides a cost-effective option to artists and stencil companies looking for a partner who can help guide them through the entire end-to-end stencil production process, from selecting the appropriate mylar material to overseeing file preparation to packaging the stencils.

Direct-to-Consumer Offering

-

LasX created the StencilSharp brand to establish an online shop for consumers to directly access and buy stencils.

Related Resources

LasX expertly cuts custom stencils.

Learn how.

Our Contract Manufacturing is robust.