LaserSharp® Marking

Where precision meets possibility.

Choose laser marking for direct-to-consumer packaging.

Conventional methods limit innovation and agility. LasX’s high-speed, high-resolution laser marking technology transforms packaging production by reaching inline production rates, reducing WIP, streamlining fragmented processes through a seamless digital workflow, and enabling instant job order changes.

Waste reduction

Our laser-enabled digital workflow supports mono-materials—eliminating the wastefulness of inks, adhesives, and other materials needed for traditional methods.

Large area coverage

Laser technology facilitates full package coverage. With LasX, you can reach surface areas that pressure-sensitive adhesives, shrink, or direct ink printing can’t.

Agile supply chain

Traditional methods are operationally complex with multiple disjointed steps. Laser marking reduces complexity and waste—enabling operational efficiency and a more cost-effective approach.

Variable data

Our laser processing technology is digitally reconfigurable, making the process of serialization, date/time codes (“best before”, “sell by”, etc), or language variation easy to achieve.

The LasX Advantage

With our LaserSharp® Marking technology, LasX delivers a sustainable, indelible, and customizable way to personalize direct-to-consumer packaging.

+Permanent marking of surface versus label peeling/tearing

+Consistent and reproducible quality at high speeds and high resolutions

+Easy-to-adjust branding in hard to reach places

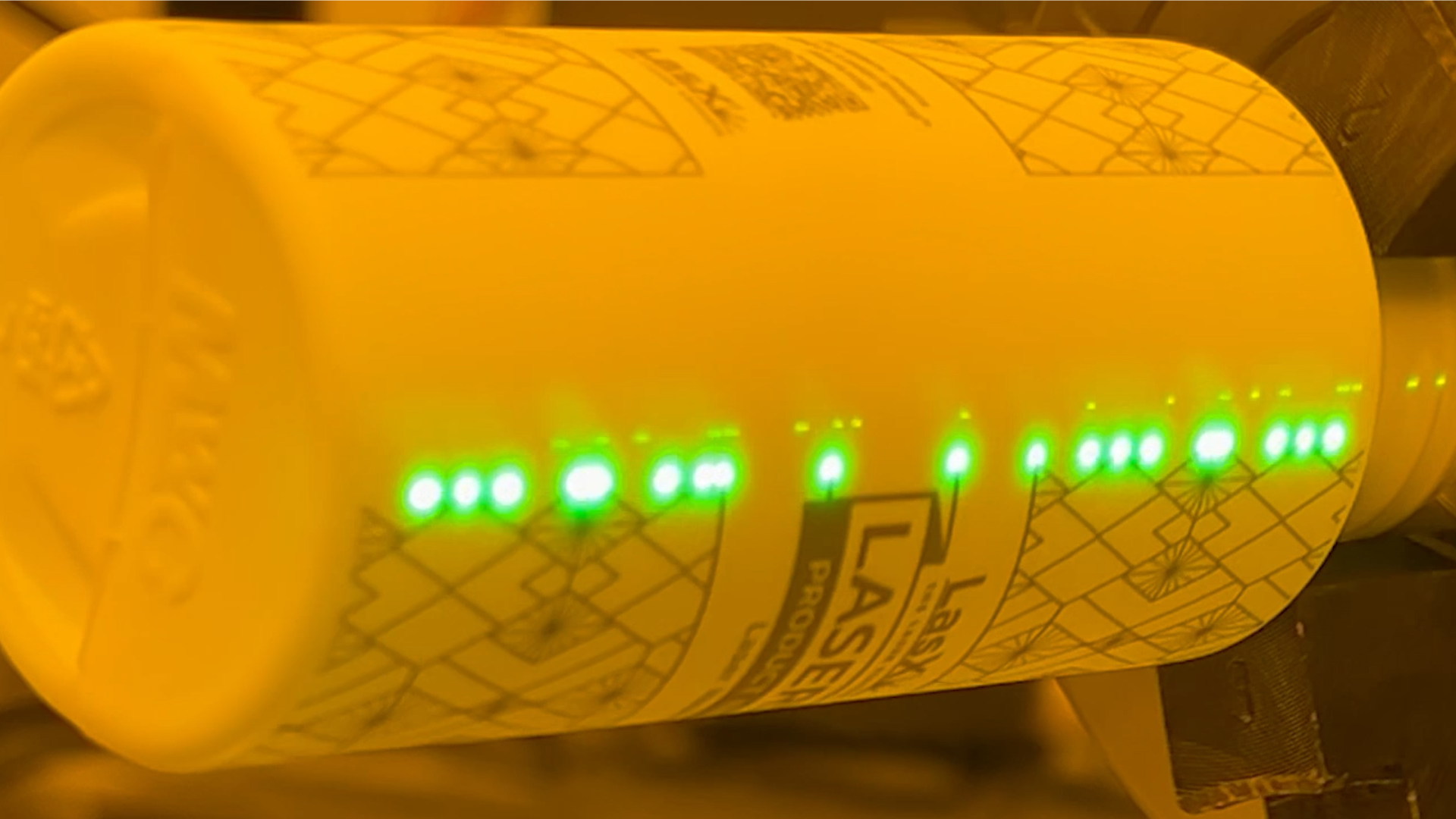

Achieving true inline production speeds

With our unique control technology, LasX marks high-resolution text and graphics directly on bottles and other packaging materials at much faster rates than conventional laser marking.

Featured applications

-

Product Embellishment

Laser marking elevates consumer goods with intricate text and graphics, textured surfaces, and personalized options like custom names or messages.

-

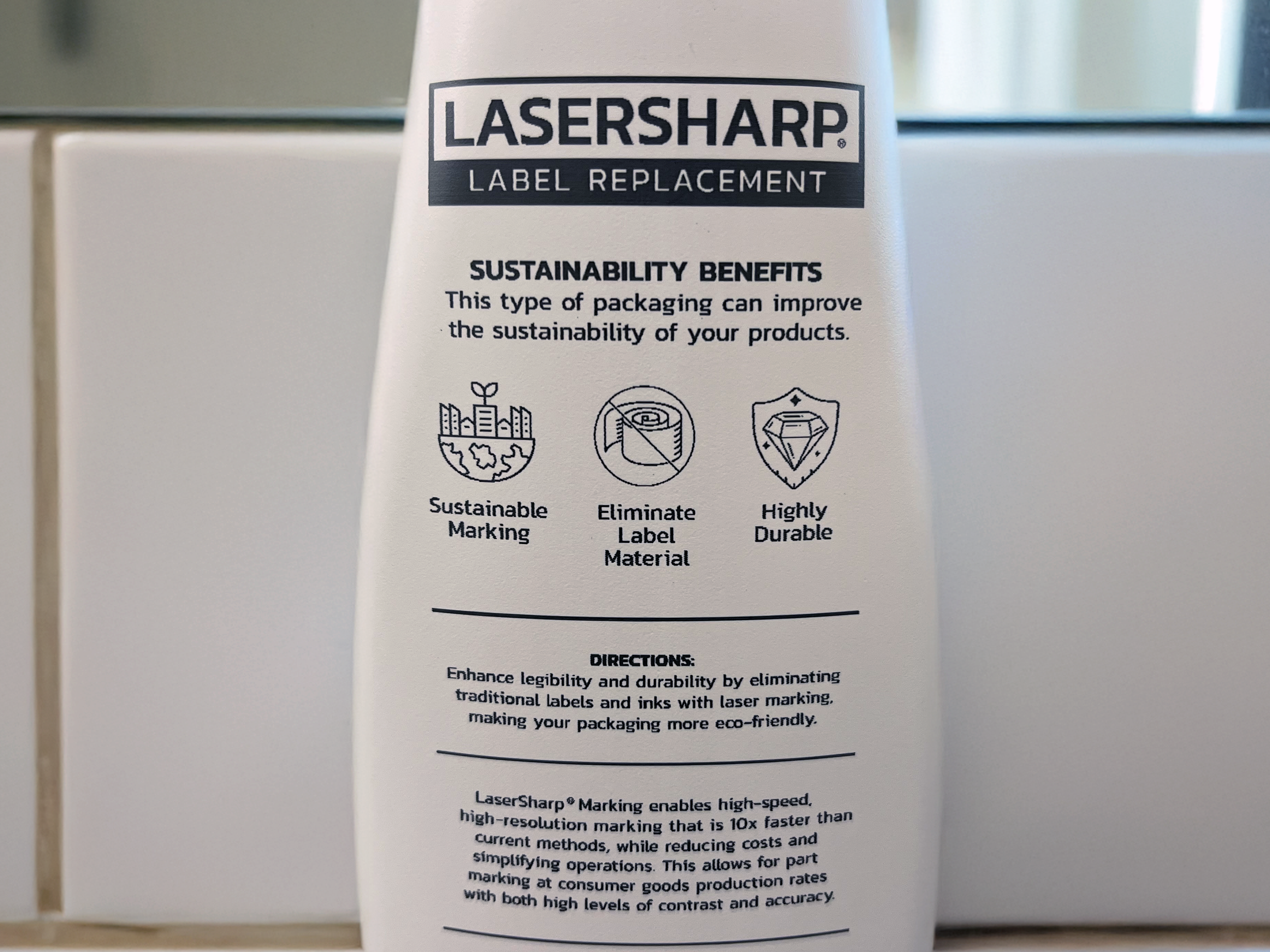

Label Replacement

Permanent, high-resolution surface marking enhances visual appeal and legibility while eliminating the risk of peeling or tearing common with applied labels.

-

Ink Replacement

Laser marking creates visible marks by altering a material's surface—no inks, dyes, or chemicals needed. It's ideal for flexible packaging and eco-friendly applications.

-

Integrated Variable Coding

Dynamic data like serial numbers, barcodes, and QR codes can be marked directly on the packaging surface, eliminating the need to reserve space for later labeling.

Material Formats

Roll Fed

Bottles & Cans

Sheet Fed

Solutions designed around you

-

Contract Manufacturing Services

LasX delivers on-demand contract manufacturing for brand owners working with consumer testing production runs.

-

Custom Equipment Development

LasX designs laser systems tailored to specific automation and processing needs, based on the laser marking application at hand.

-

OEM Integration

LasX makes it easy to integrate our laser technology into your existing equipment through guidance and installation support from our trusted team.

Success stories from LasX