Medical & Life Sciences

Where precision meets possibility.

Choose laser for the medical frontier.

Traditional manufacturing methods often fall short when it comes to meeting the intricate demands of the medical industry. Many of today’s medical innovations rely on the precision and versatility that only laser technology can provide. Laser processing not only handles delicate materials and heat-sensitive components with care, but also enables the creation of complex geometries that conventional techniques simply can’t achieve. Moreover, because lasers operate without physical contact, they minimize material damage and are ideally suited for immediate integration into cleanroom environments.

High Accuracy & Precision For Consistent Quality

Compatible With Difficult-to-Process Materials

Rapid Prototyping Without Tooling Changes

Micron-Sized Features With Tight Tolerances

The LasX Advantage.

Accelerating Innovation, From Start to Scale.

Our expert team partners with you throughout the entire product lifecycle—starting with early development and extending through to high-volume commercial production. We combine advanced laser technology with deep expertise in medical device innovation to deliver tailored solutions that meet your unique needs.

Our capabilities include:

We’re committed to delivering the right solution for your business—precisely engineered to fit your goals.

Precision-driven. Quality-assured.

Our ISO 13485-certified facility is equipped with advanced laser processing systems, cleanrooms, and a dedicated laser and motion laboratory—enabling us to deliver high-quality medical components and devices with speed and consistency.

We specialize in laser-based processes including:

Cutting

Micro-perforating

Ablating

Scoring

Marking

Our expertise allows us to process a wide range of materials with exceptional accuracy and precision.

Featured applications

-

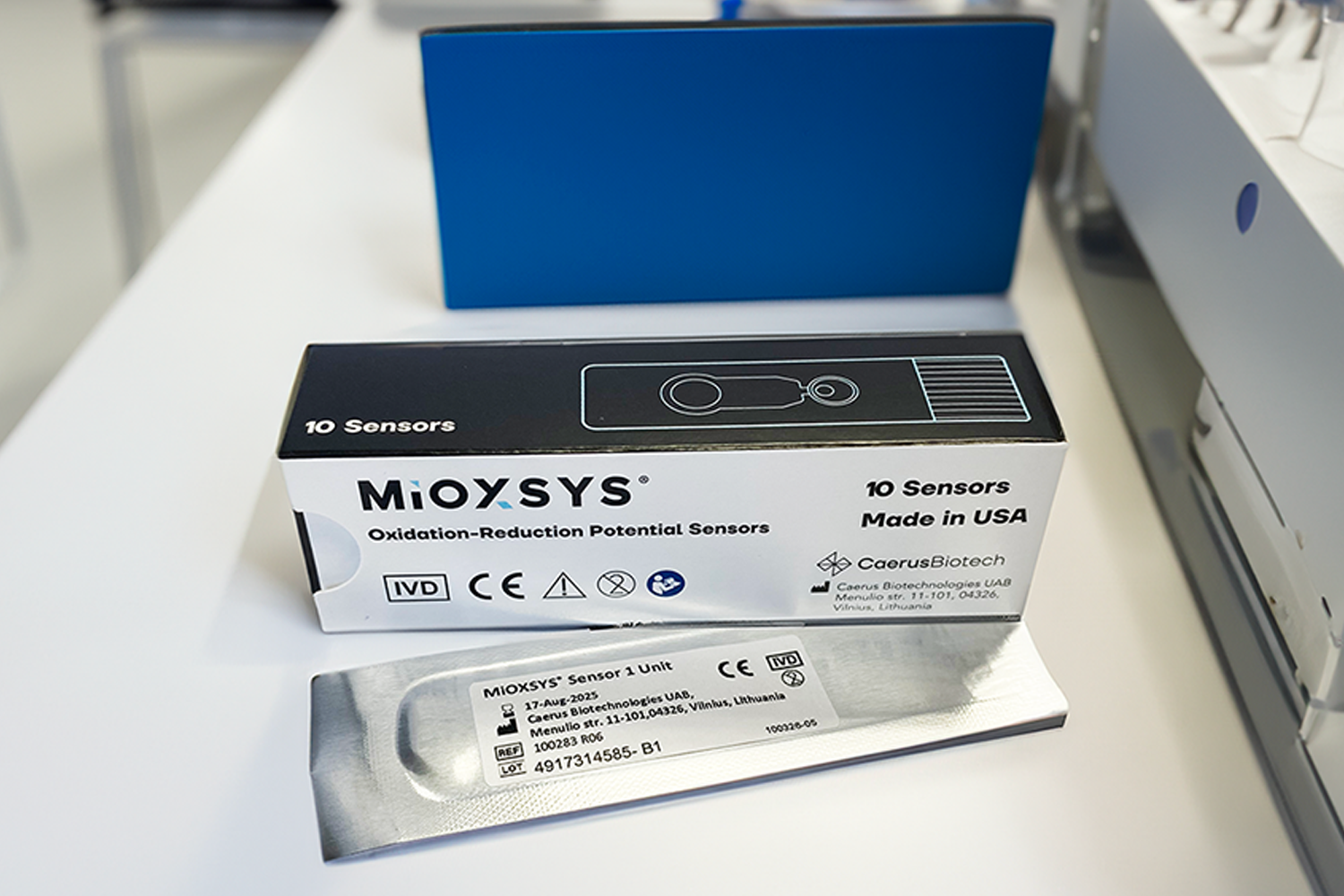

Diagnostics & LOC

We seamlessly integrate custom features, like microfluidic channels, to enhance functionality and expand diagnostic possibilities.

-

Surgical Instruments

Laser processing enables the fabrication of highly precise and durable surgical instruments, minimizing thermal distortion for superior material integrity.

-

Medical Components

With minimal setup required, we deliver medical components fast—scaling effortlessly from prototype volumes to full-scale production in the millions.

-

Surgical Apparel

Laser technology is well suited for precisely cutting and shaping non-woven textiles, including surgical gowns, drapes, and masks.

Solutions designed around you

-

Application Development & Prototyping

LasX features an in-house laser & motion laboratory for accelerating the development process for our customers.

-

Contract Manufacturing Services

We deliver intricate medical components with a confidential, quality-driven manufacturing approach.

-

Custom Equipment Development

LasX designs laser systems customized to the specific automation and processing requirements of each medical application.

Sucess stories from LasX